Fagoni Quality System

Our Formula: Precision, Know-How, and Passion

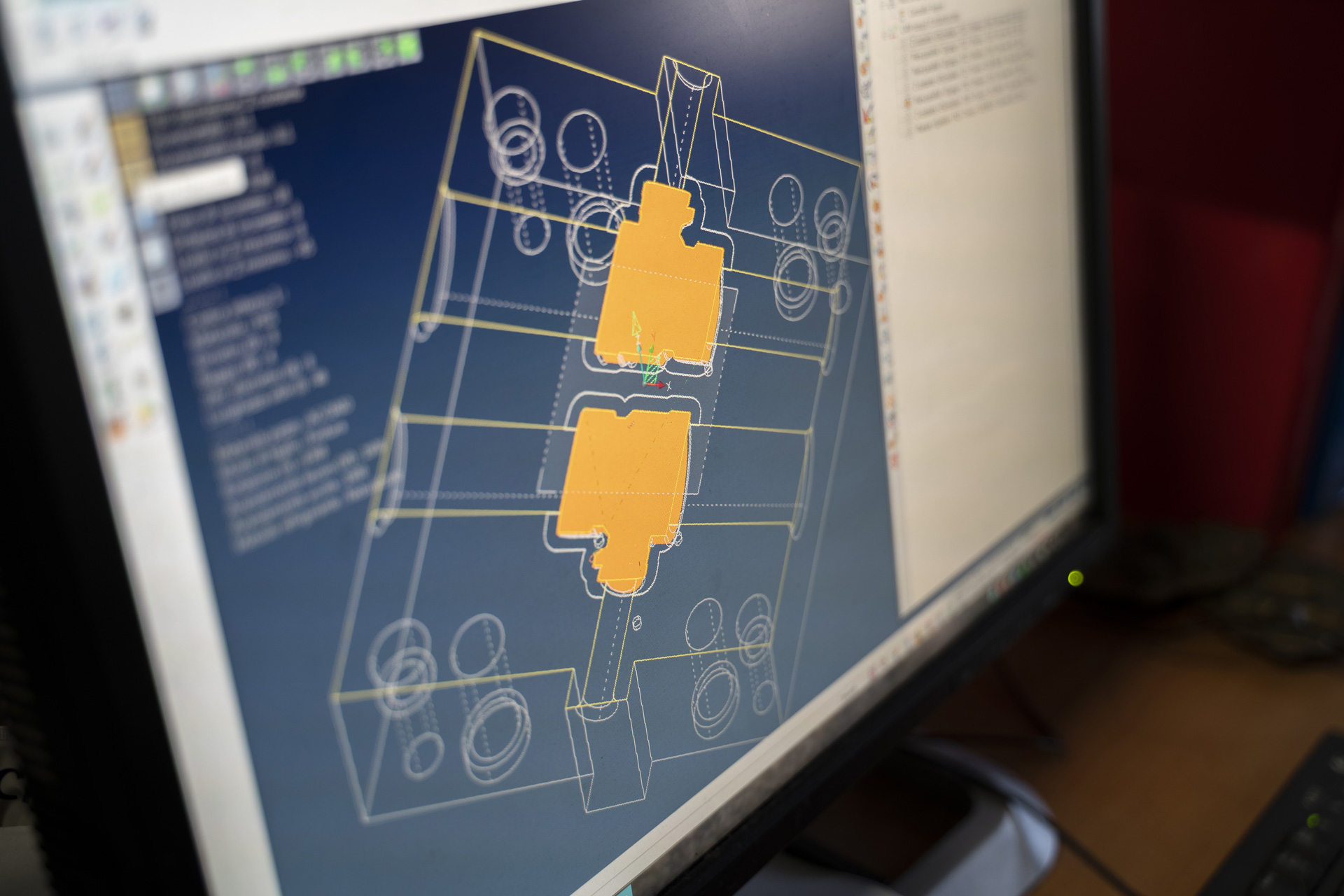

At the core of Fagoni S.r.l.’s Quality System is design, as everything starts with careful planning that must consider both the intended use and the manufacturing process in which the mold or equipment will be applied. A deep understanding of these processes ensures full control over the project and protects against errors that could compromise delivery times or the performance of the final product.

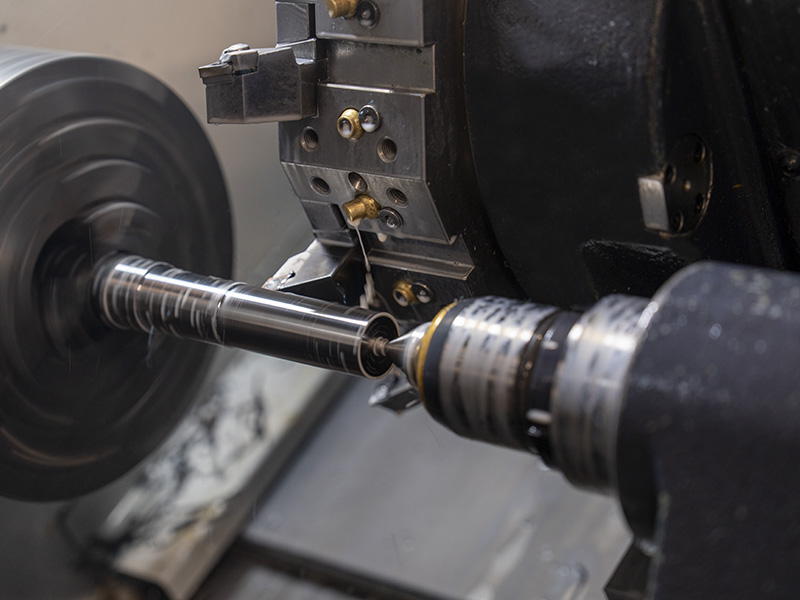

Quality control is carried out step by step. This meticulous approach to checking each intermediate stage ensures results that meet agreed expectations. Nothing is left to chance, as every part and component undergoes thorough dimensional and functional inspections.

At the company, the motto is: knowledge without experience is useless, but experience without knowledge is equally pointless. This philosophy is reinforced by a highly advanced technological department, ensuring rigorous and reliable expertise. Every project is unique, and this principle guides both Paolo and Alessandro toward a humble and professional approach to achieve and deliver the expected results.

All molds and equipment are carefully tested in every component, across all movements, and for all performance and functions, to ensure quality and reliability.

Our consultative approach continues even after the sale, providing support for modifications or upgrades, as well as adaptations (e.g., equipment changes) to ensure usability and to adjust the product for new contexts.